Project Definition

This project delves into the design and analysis of structurally efficient three-dimensional bimetallic lattice structures, aiming to achieve tailorable thermal expansion while maintaining mechanical integrity.

This comprehensive study combines theoretical analysis with finite element modeling to ensure stability, minimize deformation, and maintain the structure's original shape. The findings will contribute to the development of lightweight, robust structures suitable for various engineering applications.

Applications

The extreme thermal alternating environment in space requires the structures of the spacecraft to have high

mechanical and thermal stability to meet the requirements of electronic and optical precision instruments.

It is a common situation that different parts of satellite structures are made of materials with different

coefficients of thermal expansion (CTEs). During thermal cycling, these parts can experience thermal

expansion mismatch, which leads to shape deformations, large stresses, and damage.

Therefore, there is an urgent need for designing structures with customable and load-bearing capacity

over a wide temperature range.

Kai Wei Et al, Three dimensional lightweight lattice structures with large positive, zero and negative thermal expansion, 2018

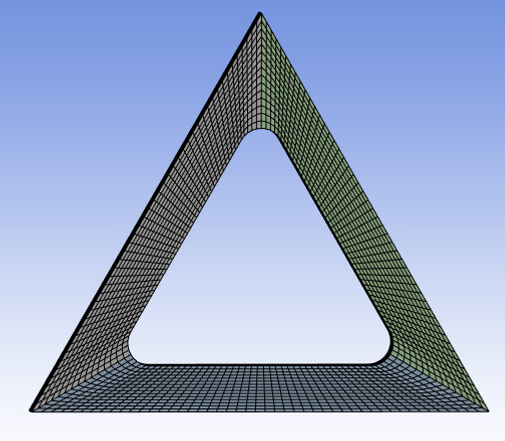

Triangular elements serve as essential foundational components in lattice structures, primarily due to their inherent geometric stability, and understanding how these triangles behave under thermal loading is essential.

The behavior of bimetallic lattice structures varies significantly

depending on the types of triangular configurations used

Solid Triangle

Pin-Jointed Triangle

Beam Element Triangle

Side Members - Low CTE Material ( Titanium Alloy )

Base Member - High CTE Material (Aluminium Alloy )

Structure heated up to 300°C

Analysis of Solid Triangle

Fixed Support at the bottom (Small circle of r= 0.5 )

Displacement ( x = free, Y=0, Z=0)

Total Deformation

Deformation in vertical direction ( Change in height )

Mesh elemental size of 0.25mm

Analysis of Pin-Jointed Triangle

Structure heated up to 300°C

Total Deformation

Fixed Support and Displacement

Deformation in vertical direction ( Change in height )

Mesh elemental size of 0.25mm

Analysis of Beam Element Triangle

Structure heated up to 300°C

Fixed Support and Displacement

Total Deformation

Deformation in vertical direction ( Change in height )

Unlike the pin-jointed or beam element structures, which allow rotational or flexural movement, the solid structure lacks flexibility at its connections leading to greater change in vertical height

Triangular frustums are an ideal 3D lattice structure due to their ability to provide structural stability while efficiently distributing loads.

Total Deformation